Steam Generator - Vertical type

HIGH EFFICIENCY - LOW CO2 EMISSION

Steam generators often comes

with very high efficiencies equal low fuel consumption and low CO2 emission.

But special request on extra high efficiencies and extra low CO2 emission

can be offered as a part of our general customized solution features. It

costs a little more, but the overall cost are normally lower - and the

environmental issue should also been taken into account.

Additional efficiency can be obtained by using an

economizer (optional extra).

LOW NOx

The steam

generators are prepared with combustion chambers for ensuring Low NOx when

choosing an appropriate Low NOx burner. This design also offer high efficiencies.

More green solution, often a request. The long term extra costs are very

often modest due to the higher efficiency.

|

NOTE! Without

a suitable combustion chamber design, no Low NOx burner can

ensure environmental values with regard to NOx emissions - the boiler design

is essential to ensure Low NOx. |

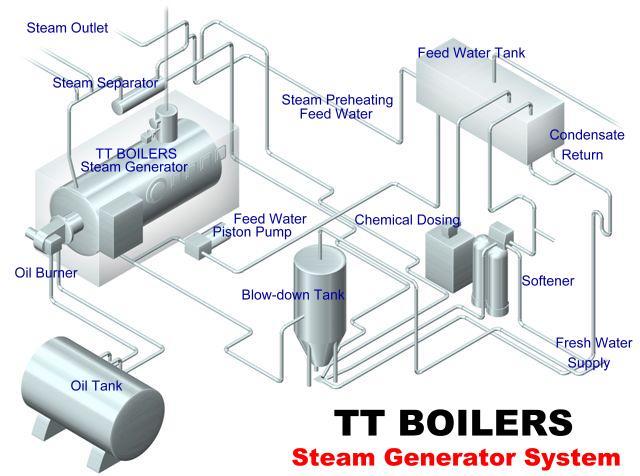

EXTENT OF DELIVERY

Steam generators can be

delivered in horizontal execution (with low height), or in vertical execution (occupying

limited floor space). They are delivered insulated with stainless steel cover sheets and

complete with burner, armatures, instrumentation, safeties and a control panel - and with

full documentation including necessary certificates.

All steam generators are

carefully checked, controlled and function tested prior to dispatch from the

workshop.

|

CONSTRUCTION

The steam generators heaters are made

with coils made of seamless tubes, where the feed water is preheated and evaporated during

the flow through these. The heat is transferred to the water/steam mixture as radiant heat

in the combustion chamber, where the inner cylindrical tube coil and a flat tube coil

forms the chamber wall and the bottom respectively. Consequently refractory concrete is

avoided. The combustion gasses are hereafter cooled in the outer convection part, as the

gasses pass the space between the two tube coils. The thermal design ensures a modest

volume of steam relative to the size of the heater, and allows unlimited thermal expansion

due to the high temperatures. All TT BOILERS steam generators and steam boilers are

designed and equipped according to German TRD boiler regulations and Danish boiler

regulations and corresponding EN-norms.

DT steam generators are made in carbon steel,

but also different grades of

stainless steel.

Making the Steam Generators

SPECIAL DESIGNS

Beside the standard execution the

steam generators can be delivered in e.g. following variations:

More info about

the 'R&D Workshop' |

BURNERS

As standard the heaters are provided by

international recognized and only high quality burner brands - for natural gas, light fuel

oil, heavy fuel oil and combinations (dual fuel). This include Low NOx

burner designs. Demands for special burner designs can

be fulfilled and adapted in the heater design.

STEAM

GENERATORS

OR STEAM BOILERS ?

There are indeed some major differences

between a steam generator and a classic 3-pass fire-tube steam boiler.

Advantages and disadvantages

are present depending on the actual circumstances.

Read more about different

type of steam boilers and about making the right choice on selecting the

Correct

Type of Steam Boiler. AB&CO offer both types and have

no preferences in advising in favour of either type.

|

|

PRODUCTION OF CLEAN STEAM

Steam

generators are also delivered for production of clean steam for food

industry, pharmaceutical industry, electronically industry etc. |

oil/gas-fired clean steam generator

Tube coil of a clean steam generator

steam generator with reboilers for pure steam

|

Sanitary steam

(clean steam) for food applications

are provided by a steam generator made in high grade

stainless steel. The photo above shows a unit

for Rolls Royce in UK which should also have other

special features such as steam of 190 barg / 350°C.

See

more

details here about

clean steam. |

|

For

pharmaceutical industry a special grade of high quality sterile steam is used

- so-called pure steam. The photo above shows steam generators with

capacity of 300 kg/h and 600 kg/h - with reboiler, grinded and

polished internally.

See

more details

here about clean steam.. |

Design

Steam Generator -

Special Customised Unit

Type

Horizontal type only |

Steam

Production

[kg/h] |

Heat

Capacity

[kW] |

Oil · Gas

Consumption

[kg/h · Nm³/h] |

A

**

[mm] |

B

[mm] |

C

*

[mm] |

D

[mm] |

E

**

[mm] |

F

[mm] |

Weight

Empty

[kg] |

Weight

Full

[kg] |

|

DTM 125 |

125 |

87 |

8,5 · 9 |

1700 |

1300 |

800 |

700 |

800 |

Ø150 |

150 |

175 |

* Measurement including control panel , which can

be placed anywhere or delivered separately.

** Measurement adjusted

with respect to nozzles (inlet feed water, outlet steam) which are located

at the front.

Type |

Steam

Production

[kg/h] |

Heat

Capacity

[kW] |

Oil · Gas

Consumption

[kg/h · Nm³/h] |

A

[mm] |

B

[mm] |

C

[mm] |

D

[mm] |

E

[mm] |

F

[mm] |

Weight

Empty

[kg] |

Weight

Full

[kg] |

|

DT 300/100 |

100 |

67 |

7 · 7 |

1,800 |

1,400 |

1,400 |

1,000 |

1,500 |

ø210 |

440 |

460 |

|

DT 300/150 |

150 |

100 |

10 · 10 |

1,900 |

1,400 |

1,400 |

1,000 |

1,500 |

ø210 |

445 |

465 |

|

DT 300/300 |

300 |

200 |

20 · 21 |

2,000 |

1,400 |

1,400 |

1,000 |

1,500 |

ø210 |

450 |

470 |

|

DT 300/400 |

400 |

266 |

26 · 28 |

2,100 |

1,400 |

1,400 |

1,000 |

1,500 |

ø210 |

455 |

475 |

|

DT 600/700 |

700 |

466 |

46 · 49 |

2,550 |

1,850 |

1,500 |

1,100 |

1,500 |

ø250 |

600 |

650 |

|

DT 1000/800 |

800 |

533 |

52 · 56 |

2,900 |

2,400 |

1,600 |

1,200 |

1,800 |

ø350 |

1,285 |

1,385 |

|

DT 1000/1000 |

1,000 |

666 |

65 · 70 |

3,100 |

2,400 |

1,600 |

1,200 |

1,800 |

ø350 |

1,300 |

1,400 |

|

DT 1000/1200 |

1,200 |

800 |

78 · 84 |

3,300 |

2,400 |

1,600 |

1,200 |

1,800 |

ø350 |

1,325 |

1,425 |

|

DT 1500 |

1,500 |

1,000 |

98 · 105 |

On request |

|

DT 2000 |

2,000 |

1,333 |

130 · 139 |

All below figures and data are

estimations for guidance only. The exact capacity appears from

the quotation. Exact sizes to be determined as part of order

effectuation and adjustment of the customised design.

Since most AB&CO

models are customised units, the above figures only represent some of the

available sizes.

Above models are all oil or gas-fired, while dimensions on

electrical heated models can be provided on request.

For using above table you should choose the size above your required

heat capacity, to get the dimensions and weight for the unit.TABLE VALUES · Presumptions:

The below stated values for heat capacity and fuel consumptions are based on

80°C

feed water temperature, 7 bar steam pressure, 90% efficiency and normal European quality

light fuel oil (LCV=42 MJ/kg) and natural gas (LCV=40 MJ/Nm³) |

|

CONTAINERISED STEAM BOILER

ROOM An

option is the container solution, comprising all

equipment for ensuring a efficient steam production.

Containerized solutions are used widely as an fast and economical way to

establish steam up to 2400 kg/h.

It can be used as an emergency steam

back-up, when a steam supply fails and a fatal situation occurs. With a

container solution you can rapidly be "on-steam" again.

This solution is used

for end-user of steam, but it is certainly also as an attractive business opportunity

to buy these for renting out

- and thus offering the above services to end-users.

Steam generator boiler are also available

in:

Read more about mobile solutions

|

Delivery options

10 / 20' containers :

Up to 1200 kg/h steam

operating pressures 1 - 190 bar

Up to 2400 kg/h steam

on two steam generator boilers

operating pressures 3 - 190 bar

|

|

|