|

|

|

THERMAL FLUID SYSTEMS

Industrial

Thermal

Oil (HTF) Heating Systems

Above diagram and photo are examples of a thermal

oil heating system according DIN 4754 for process

air heating.

|

|

AB&CO thermal fluid heating systems are high temperature process

heating systems, that uses a special thermal oil, a so-called

Heat Transfer Fluid (HTF), as the circulating heat carrier.

These types of heating systems are used for high performance industrial

processes - most often as an alternative to high pressure

saturated steam.

They become an attractive alternative

to the steam mainly due to much higher operating temperatures

on the media (HTF), maintaining low system pressure (often

atmospheric pressure). But there are numerous other

advantages, including

significant less overall operation costs. See more at "COMPARE

STEAM AND THERMAL FLUID".

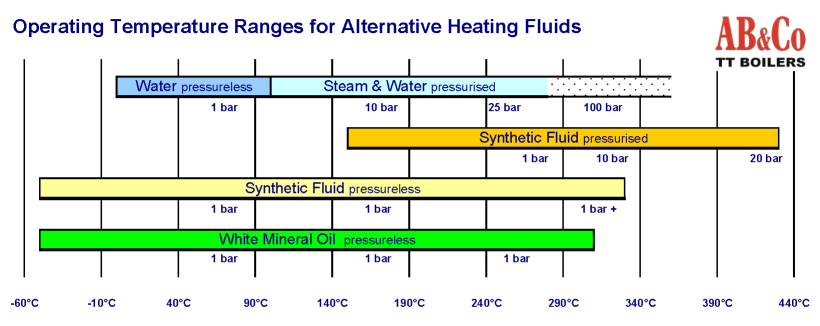

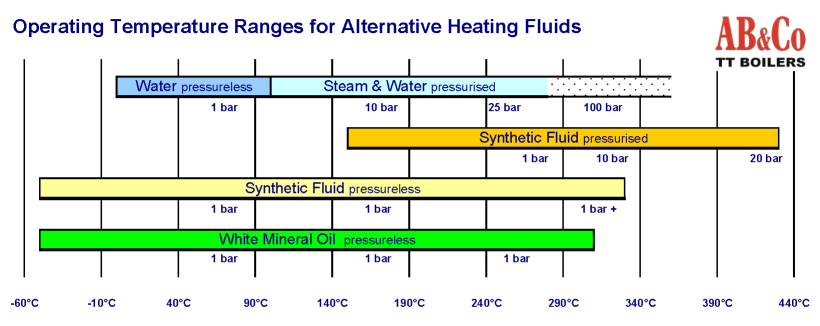

As it appears from diagram below, steam at high temperatures

requires pressurised systems, whereas thermal oil (HTF) can be

operated atmospheric up to above 300°C. When pressurised,

the HTF can be operated even up to 400°C. |

The ThermoPack is a

AB&CO heater

including

accessories, all

skid-mounted

in a unit,

operating unpressurised i.e.

atmospheric, and

with operating

temperatures up to 300°C

Container-solution of a thermal oil

systems, including AB&CO heater

with burner using access fish-oil as fuel.

AB&CO electric thermal oil

heater

for 400°C - moderate

pressurised thermal fluid.

General Principle in

AB&CO Oil- and Gas-fired

Thermal Oil Heaters

|

Above in higher quality

Above in higher quality

Properties Steam/Water

Properties Steam/Water  Properties

HTF (typically white mineral oil type)

Properties

HTF (typically white mineral oil type)

|

The

ThermoPack units (thermal oil heater units) comprise a heater,

pressure vessel, main pump, heat exchangers,

tanks, armatures, safety equipment, instrumentation, control system and the

tanks for expansion, dearating & de-gassing, buffer and emptying including

arrangement for filling/emptying system, barrels and tank.

The standard follows European code including PED 2014/68/EU, EN-standards and

the recognised and demanding German standard for thermal oil heating systems

DIN 4754.

All AB&CO systems includes the heaters - whether they are oil-fired,

gas-fired, electrical heated or exhaust gas recuperative.

They are delivered

with a full documentation package comprising drawings, diagrams, data

sheets, specifications, instructions for installation, handling, operating

and maintenance - and all required certificates necessary for deliveries

within the EU.

Environmental solutions are

available in many alternative design - including mounting of economiser and thermal oil

heated by utilising waste heat in, for instance, hot flue gas.

AB&CO have

specialised in ThermoPacks as skid-mounted units and containerised solutions

(as shown on photo above / left). But systems are also delivered as separate

components e.g. the heaters alone (below photo)

AB&CO oil-fired heaters at bitumen plant |

The simple principle in thermal thermal fluid systems is heating by use

of a special thermal

oil - also called heat transfer fluids (HTF).

The HTF circulating through heaters (whether they are with

burners, electrical elements or as flue gas recuperators).

Thereafter

the HTF is led through a piping to one or several consumers, which can be for instance heat exchangers, air

heaters, tanks. reactors, convectors, rollers etc.

AB&CO process air heat exchanger

during

final inspection by

customer from Germany.

These systems are all tailor-made and they are

always delivered as complete packages for assembly on site, or as

skid-mounted units when the size allows it. They come with full documentation and easy

readable instructions for handling, erecting, installation operation and maintenance. |

SPECIAL

SERVICE

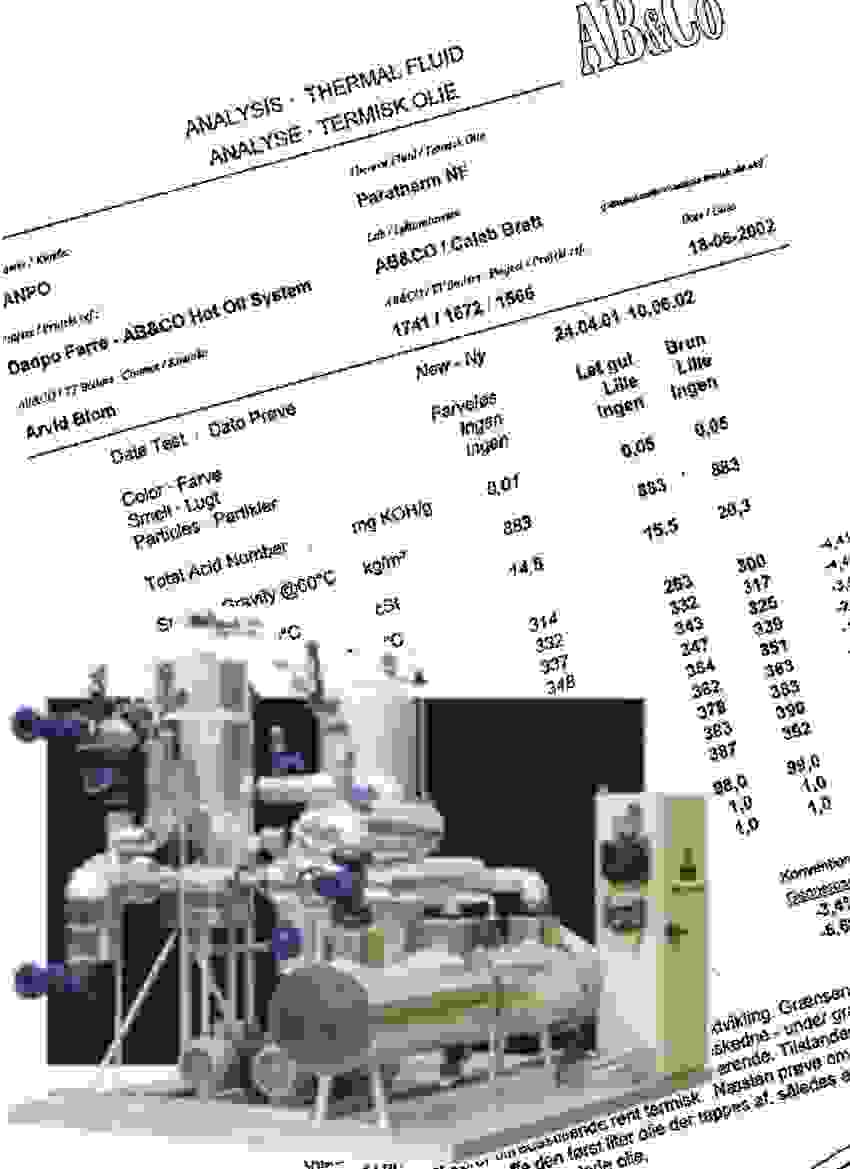

The engineers of AB&CO are able to assist in the operation of the thermal fluid heating

system by frequently analysing samples of the circulating oil. From the

analysis it is possible to guide for an optimum performance and long life

time for both the oil and the plant.

For more extensive assistance in optimising new or existing systems, or for

trouble shooting - consider our

Consultant Services.

|